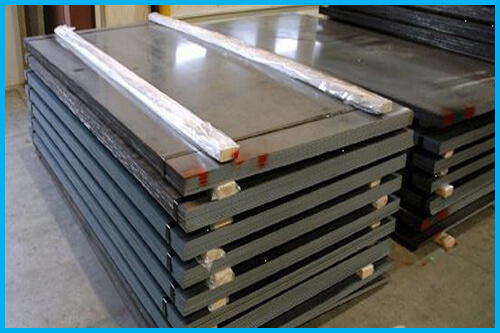

Looking to reduce equipment downtime, extend service life, and control maintenance costs in abrasive operating environments? Wear Plates are engineered to deliver superior resistance against abrasion, impact, and material loss across demanding industries. Designed for performance-driven buyers, Wear Plates provide consistent durability, predictable wear behavior, and long-term cost efficiency—making them an essential material choice for heavy-duty applications.

Why Buyers Prefer Wear Plates

Buyers across mining, construction, cement, and material handling industries increasingly prefer wear plates because they directly address one of the biggest operational challenges—premature equipment failure due to abrasion. Instead of frequent replacements and costly shutdowns, wear-resistant plates ensure longer component life and stable performance.

From a procurement and operational standpoint, wear plates deliver measurable value. They protect critical equipment, improve productivity, and reduce total cost of ownership. Moreover, modern wear plates offer improved weldability and formability, allowing easier fabrication and faster installation.

Key buyer-driven benefits include:

- Exceptional abrasion resistance in sliding, gouging, and impact conditions

- Extended service life, minimizing maintenance and replacement cycles

- Improved operational uptime, increasing productivity

- Consistent hardness and quality, suitable for repeat procurement

- Cost-effective protection for high-wear zones

- Wide grade availability, matching specific wear conditions

As a result, buyers rely on wear plates as a strategic investment rather than a consumable expense.

Technical Specifications of Wear Plates

Understanding technical specifications allows buyers to select the right wear plate grade for their specific operating conditions. Below is a general overview of commonly supplied wear plate specifications.

Chemical Composition (Typical % – Varies by Grade)

- Carbon (C): 0.15 – 0.35

- Silicon (Si): 0.20 – 0.60

- Manganese (Mn): 1.00 – 1.70

- Phosphorus (P): ≤ 0.025

- Sulfur (S): ≤ 0.010

- Chromium (Cr): 0.30 – 1.50

- Nickel (Ni): ≤ 0.70

- Molybdenum (Mo): ≤ 0.50

- Boron (B): Trace (for hardenability in higher grades)

This alloy-controlled composition ensures uniform hardness, excellent wear resistance, and reliable performance across thicknesses.

Mechanical Properties

- Hardness Range: 360 – 550 HBW (depending on grade)

- Tensile Strength: 1200 – 1500 MPa (typical)

- Yield Strength: 900 – 1200 MPa (typical)

- Impact Resistance: Moderate to good, depending on grade selection

These mechanical properties allow buyers to match wear plates precisely to abrasion intensity and impact conditions.

Available Forms

- Wear-resistant plates

- Sheets

- Cut-to-size blanks

- Profile-cut components

- CNC plasma- or laser-cut parts

Applications

- Mining liners, buckets, and chutes

- Quarrying and crushing equipment

- Cement plant liners and hoppers

- Earthmoving and construction machinery

- Dump truck bodies and skip liners

- Recycling and bulk material handling systems

International Standards & Equivalent Grades

Wear plates are produced in accordance with globally recognized standards, enabling buyers to integrate them into international projects and specifications.

- UNS: No direct UNS designation (abrasion-resistant steel grades)

- ASTM: ASTM A514 / AR400 / AR450 / AR500 (grade-dependent)

- ASME: ASME SA514 (pressure and structural wear applications)

- DIN/EN: EN 10051, EN 10204, EN 10025-6 (application-specific references)

These standards provide confidence in material quality, traceability, and performance consistency.

Regional Market Focus

- India: Strong demand in mining, cement, power, and infrastructure sectors

- Germany: Preferred for precision-fabricated wear components and OEM manufacturing

- UK: Widely used in recycling, quarrying, and heavy fabrication industries

- UAE: High adoption in construction, mining, and bulk material handling projects

Why Partner with Vandan Steel & Engg.co

For buyers, sourcing wear plates is not just about material—it’s about reliability, documentation, and service support. Vandan Steel & Engg.co delivers a buyer-oriented supply experience built on trust and performance.

- Complete Mill Test Certificates (MTCs) with every order

- Flexible MOQs to support small projects and bulk requirements

- Reliable domestic and international logistics solutions

- Dedicated technical support for grade selection and application guidance

- Consistent quality, traceability, and on-time delivery

By partnering with Vandan Steel & Engg.co, buyers gain a dependable supply chain that supports long-term operational efficiency.

Source High-Performance Wear Plates – Contact Us Today

If your operations demand longer equipment life, reduced downtime, and improved cost efficiency, wear plates are the proven solution. Choose a supplier who understands buyer priorities and industrial wear challenges.

Vandan Steel & Engg.co

???? 359 / 373, Flat -9, 2nd Floor, Minerva Mansion, Svp. Road, Khetwadi, Giragoan, Mumbai -400004.

???? +91-8828813630

✉️ [email protected]

Contact us today for pricing, technical consultation, and fast delivery—and strengthen your operations with wear-resistant solutions engineered for performance and reliability.